Business

Business

Key Factors to Consider When Choosing a UPVC Pipe Manufacturer

- Quality and Certification Standards

- ISO 9001 – Quality Management System

- IS 4985 – Indian Standard for UPVC pipes used in potable water supply

- ASTM D1785 – American Standard for UPVC pipes for water distribution

- BS EN 1329 – European Standard for UPVC drainage pipes

- Manufacturing Technology and Process

- Precision in wall thickness and dimensions

- Advanced resin formulation to enhance UV resistance

- Rigorous quality checks and testing protocols

- Raw Material Quality

- Better resistance to corrosion and chemicals

- Smooth internal surface for efficient fluid flow

- Longer lifespan with minimal maintenance

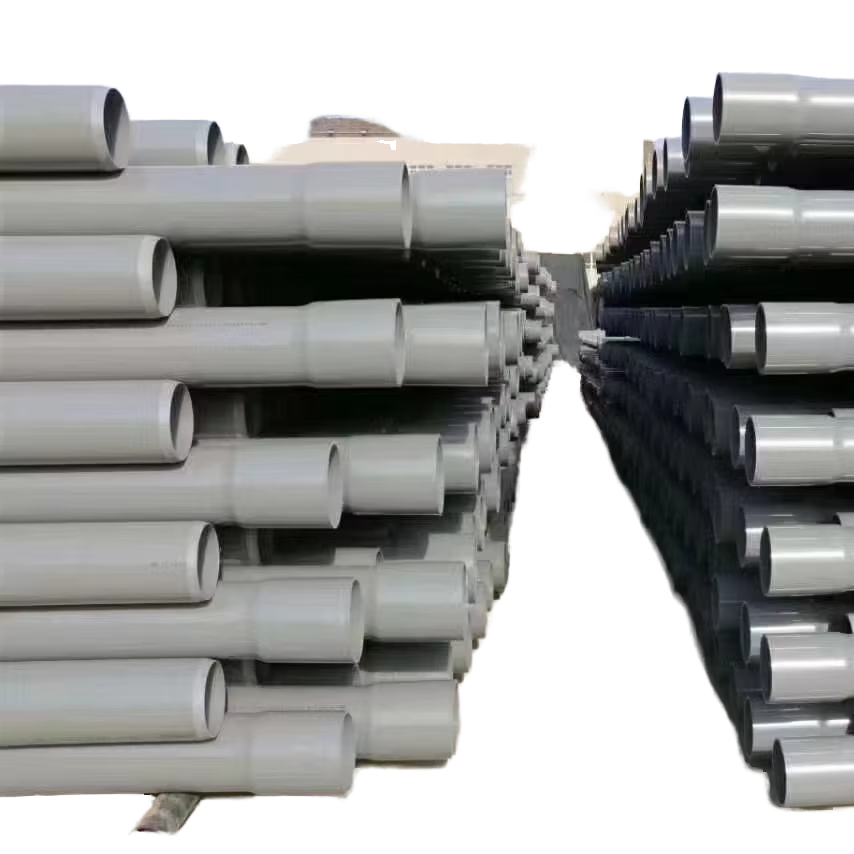

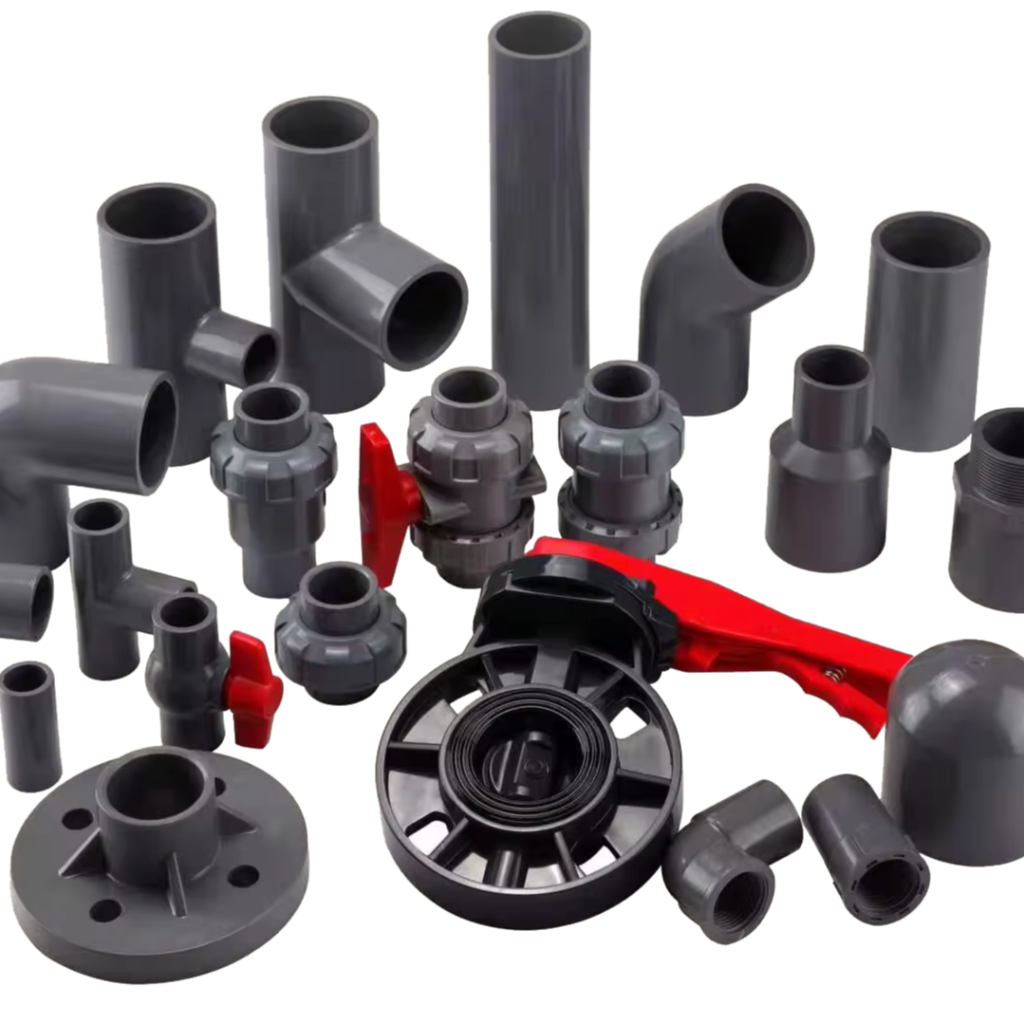

- Product Range and Customization Options

- UPVC pressure pipes for water supply

- UPVC plumbing pipes for residential and commercial use

- UPVC drainage pipes for sewage systems

- Customized UPVC pipe solutions for specific industries

- Strength, Durability, and Performance

- Withstand high pressure without cracking

- Resist chemical corrosion and UV degradation

- Have a long service life (over 50 years) with minimal maintenance

- Offer high impact strength for underground applications

- Pricing and Cost-Effectiveness

- Competitive pricing without sacrificing quality

- Bulk purchase discounts for large-scale projects

- Transparent pricing with no hidden costs

- Industry Experience and Reputation

- Decades of experience in the plastic piping industry

- Strong market presence and a proven track record

- Positive reviews and testimonials from clients

- Successful projects across different industries

- Testing and Quality Assurance

- Hydrostatic Pressure Test – Ensures that pipes can withstand high pressure without bursting

- Tensile Strength Test – Measures resistance to pulling forces

- Impact Resistance Test – Determines the pipe’s ability to handle external shocks

- Chemical Resistance Test – Confirms non-reactivity to various chemicals

- Supply Chain and Delivery Capabilities

- A well-established distribution network

- Sufficient production capacity to meet bulk orders

- On-time delivery and logistics support

- After-Sales Support and Warranty

- Technical assistance for product selection and installation

- Product warranties for defects or performance issues

- Responsive customer service for inquiries and complaints

Conclusion

Selecting the right UPVC pipe manufacturer is essential for ensuring high-quality, durable, and cost-effective piping solutions. By considering factors like certification standards, raw material quality, manufacturing technology, durability, pricing, and after-sales support, you can make an informed decision that meets your project’s requirements. For industries looking for trusted UPVC pipe manufacturers, conducting thorough research and evaluating these key factors will ensure that you choose a manufacturer that delivers superior quality and long-term reliability.Looking for a Reliable UPVC Pipe Manufacturer?

Ensure you partner with an industry leader that meets all quality standards and offers the best solutions for your piping and plumbing needs!

petronthermoplast

PETRON THERMOPLAST is a leading pipe manufacturer & consultant for Thermoplastic Industrial engineering products. Industrial turnkey to supply & installation, and fabrication of All types of Industrial Thermoplastic piping systems like UPVC, CPVC, PPH, ABS, PVDF, HDPE, PVC Pipes, UHMW plastic machining, machined parts, Gear Manufacturing, peek material and Fittings, injection molding, precision machining, etc. Our products are procured by our customers from both domestic and international regions.