Business

Business

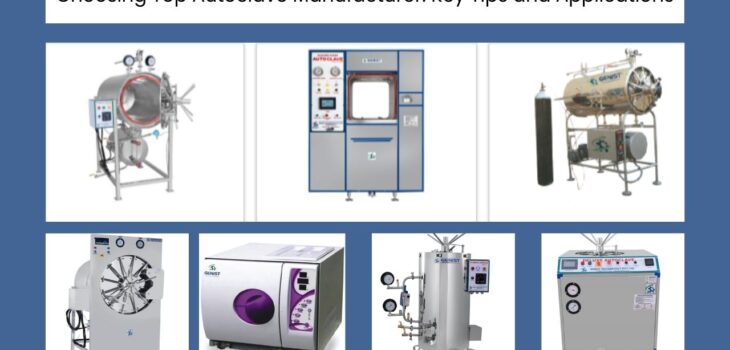

Choosing Top Autoclave Manufacturer: Key Tips and Applications

Choosing the right autoclave manufacturers in India is of utmost importance in industries where sterilization forms the basis for various activities. For example, in the healthcare, pharmaceuticals, and food processing industries, The following tips will assist you in evaluating the top autoclave manufacturer in India to meet your needs.

Define Your Requirements Clearly

Define your immediate sterilization requirement before starting the research. The type and size of different autoclaves depend on the industry using the equipment. In healthcare, autoclaves are used to sterilize instruments, and in the food industry, they are used for preservation.

Capacity: Select an autoclave on the volume required for sterilization.

Type- manual or automated selection: Automated models have higher precision and efficiency but tend to be costlier.

Temperature and pressure: Ensure the right conditions for sterilization according to your industry can be brought about in the autoclave.

Examine the Reputation of the Manufacturer

A top autoclave supplier’s reputation is key to buying an autoclave. You can check the following:

Experience: Look for manufacturers that have been in the industry for years. It is easy for experienced companies to have the most technical knowledge on how to make good-performing autoclave machines.

Customer reviews, feedback, and testimonials: They provide essential insights about product reliability and customer service.

Certifications: Any manufacturer must possess industry-recognized certifications like ISO 9001, proving they adhere to quality standards.

Assess the Features and Quality of Your Product

It cannot be stressed enough how important quality is when selecting an autoclave. The following things would need to be kept in perspective:

Material: Stainless steel is by far the most common fabrication material due to its toughness, corrosion resistance, and capacity to withstand extreme temperatures and pressure.

Technology and Qualities: Autoclaves will be selected for advanced technology features such as automatic temperature control, digital display, and energy-efficient operation, which are features enhancing efficiency and ease of use.

Energy Efficiency: Save costs over the years with the purchase of energy-efficient models because of rising energy prices.

Post-Sales Support

A suitable autoclave from a top autoclave supplier will come with excellent after-sale support to ensure the continuous performance of the autoclave. Consider the following from the manufacturers:

Warranty and Maintenance Package: Good and reliable warranty and maintenance packages indicate good faith in the product’s sustainability.

Technical Assistance: Prefer manufacturers with timely and accessible technical support for instances of malfunction or any other issue.

Spare Parts Availability: Check to see whether the manufacturer supplies readily available spare parts to minimize extended downtimes.

Cost versus Value Considerations

Cost is undoubtedly an important factor; however, there are points to consider on worth before price. Cheap might turn out to be costly in terms of maintenance or repairs for an autoclave. Some of those were:

Total Cost of Ownership: This includes checking for installation, maintenance, energy, and spare costs.

Spare Costs: Consider all extra shipping, installation, or training fees.

Customization: Some manufacturers will offer customizations to suit your particular requirements. Though this can inflate the initial cost, it may well pay off in the long run.

Compliance with Standards

Verify the autoclave manufacturer’s compliance standards. In terms of healthcare or pharmaceutical standards, compliance with a guideline, such as Good Manufacturing Practice (GMP), or a certification from a relevant agency, like the FDA and CE, might be required, as these address safety and reliability issues concerning the product.

Uses of Autoclaves in All Companies

1. Medical

Autoclaves are vital for hygiene and preventing the transmission of infection. Their most important use is sterilizing surgical instruments, such as surgical tools, forceps, and dental instruments. Autoclaves will ensure that these tools are free of any pathogenic entities, thus providing a safe environment for operations and medical procedures.

Besides, autoclaves sterilize surgical supplies, such as surgical gowns, gloves, and drapes, which should be free from contamination for infection prevention during an operation.

Another key purpose of autoclaving in healthcare is sterilizing implants and medical devices before their use during surgical procedures. Autoclaving ensures that these constituent devices, such as prosthetics, are biocompatible and pathogens-free.

Moreover, autoclaves have a significant role in preventing health-care-associated infections (HAIs) that are widely feared in the medical setting by the strict conduct of the sterilization procedure.

2. Laboratory Applications

In laboratories, autoclaves are necessary to keep sterile conditions during experimentation. They sterilize glassware, such as beakers, flasks, and test tubes, for honest and contamination-free research. Likewise, all metal instruments such as forceps, scalpels, and scissors used in laboratory settings would be autoclaved to keep them sterile.

Similarly, autoclaves sterilize almost all liquid culture media, including nutrient broths, buffers, and growth media, that are required to culture microorganisms. Likewise, autoclaves help provide a secondary line of defense by decontaminating biological waste and preventing the spread of hazardous materials. This sterilization procedure aims to ensure research integrity and safety for laboratory personnel.

3. Food Industry Applications

Among food industries, autoclaves are used for food preservation, particularly in canning and packaging, where the food is being sterilized within sealed cans or jars. This sterilization destroys bacteria, yeasts, and molds so that the food will not spoil, thus ensuring the products are treated with the most extended shelf life.

Autoclaves, in particular, need to be used in the preservation of low-acid foods, which include meats, vegetables, and sauces; in this case, food is treated at high temperatures to disallow the growth of harmful microorganisms such as Salmonella and E.Coli.

In addition, the autoclaving process also helps ensure that the food’s nutritional value, flavor, and texture are retained, even with an extended shelf life. Autoclaving uniformly distributes heat around the food product to ensure complete sterilization, fulfilling the rigorous demands of food safety guidelines.

Conclusion

If you need autoclaves to enjoy their applications in the medical, laboratory, or food industries, you can start your search for a reliable manufacturer. Your choice of the best autoclave manufacturer in India depends upon the requirements, reputation of the manufacturer, product quality, cost-effectiveness, and after-sales support.

Once you select the top autoclave manufacturer in India, you are sure of a durable, efficient sterilization solution that will greatly support your operations via premium service for the long-term success of your sterilization process.

Read Also:- Circuiting Sustainability: RoHS Certification for Modern Manufacturers