Uncategorized

Uncategorized

Washing Machine PCB Repair vs. Replacement: What’s the Best Option?

- by aldahome

The Printed Circuit Board (PCB) is the brain of your washing machine, controlling various functions like washing cycles, water levels, and spin speed. When a washing machine malfunctions, a faulty PCB is often the cause. The big question then arises: Should you repair or replace the PCB? In this blog, we will explore the pros and cons of both options to help you make an informed decision.

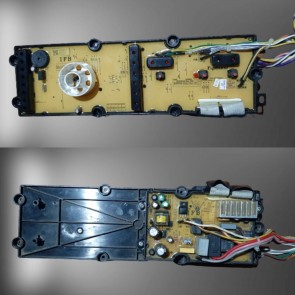

Understanding the Washing Machine PCB

The PCB is an electronic component that regulates your washing machine’s operations. It consists of microchips, capacitors, and resistors, all working together to execute commands. If your washing machine stops working, doesn’t start, or behaves erratically, the PCB could be the culprit.

How Does the PCB Work?

The washing machine PCB serves as the central processing unit, receiving signals from various sensors and executing programmed operations accordingly. It ensures that the machine follows the correct wash cycles, controls the water temperature, and regulates the motor speed. When a PCB malfunctions, it can disrupt the entire functionality of the appliance, leading to inefficient or non-operational washing machines.

Signs of a Faulty Washing Machine PCB

Before deciding whether to repair or replace the PCB, look for these common issues:

- Machine Not Powering On – A completely dead washing machine may indicate a damaged PCB.

- Error Codes Displayed – Many modern machines show error codes related to PCB failure.

- Unresponsive Controls – Buttons not working or delayed response could be due to a faulty PCB.

- Water Filling and Draining Issues – The PCB controls these functions, and failure can lead to improper water flow.

- Inconsistent Wash Cycles – If the machine skips or gets stuck in cycles, the PCB may be faulty.

- Burnt Smell or Visible Damage – A burning smell or scorched marks on the PCB indicate electrical damage.

When to Repair Your Washing Machine PCB

Pros of Repairing:

- Cost-Effective – Repairing is often cheaper than buying a new PCB.

- Quick Fix – Minor faults like burnt components or loose connections can be repaired easily.

- Eco-Friendly – Repairing reduces e-waste and promotes sustainability.

- Retains Original Settings – Repairing allows you to keep the original PCB settings, avoiding compatibility issues.

Cons of Repairing:

- Temporary Fix – If the PCB is severely damaged, repairs might not last long.

- Limited Availability of Components – Some older PCB models may not have easily available parts.

- Skill Requirement – PCB repairs need professional expertise, as DIY attempts may worsen the issue.

- Potential Recurring Failures – A repaired PCB may fail again, leading to additional repair costs over time.

When to Replace Your Washing Machine PCB

Pros of Replacement:

- Long-Term Solution – A new PCB ensures reliability and extended machine life.

- Better Performance – New PCBs improve efficiency and restore full functionality.

- Warranty Benefits – Most new PCBs come with a manufacturer’s warranty.

- Updated Technology – Newer PCBs come with improved features and enhanced durability.

Cons of Replacement:

- Expensive – A new PCB can be costly, especially for high-end washing machines.

- Compatibility Issues – Finding the exact PCB model for older machines can be challenging.

- Installation Costs – Professional installation adds to the total expense.

- Longer Downtime – Ordering and installing a new PCB may take time, leaving you without a working washing machine for days.

How to Decide: Repair or Replace?

Consider these factors before making a decision:

- Age of the Washing Machine – If your machine is old, replacement might be more practical.

- Cost Difference – If repairs cost nearly as much as a new PCB, replacement is a better choice.

- Extent of Damage – Minor issues can be repaired, but major circuit failures require replacement.

- Availability of Spare Parts – If the required components are unavailable, a new PCB is the only option.

- Future Reliability – If the washing machine has other potential issues, replacing the PCB might not be a long-term solution.

Tips to Maintain Your Washing Machine PCB

To avoid frequent PCB issues, follow these maintenance tips:

- Use a Voltage Stabilizer – Protect the PCB from power fluctuations.

- Keep the Machine Dry – Moisture can damage electronic components, so ensure proper ventilation.

- Avoid Overloading – Excess weight puts extra strain on the machine’s electrical system.

- Regular Cleaning – Keep the control panel and PCB area clean and dust-free.

- Timely Repairs – Address minor electrical issues before they cause PCB failure.

Conclusion

Both repairing and replacing a washing machine PCB have their pros and cons. If the damage is minor and cost-effective to fix, repairing is a good option. However, if the PCB has severe damage and frequent failures, replacing it ensures long-term efficiency.